Flow Measurement Challenges in Subsea Operations

Brian Craig

September 29, 2025

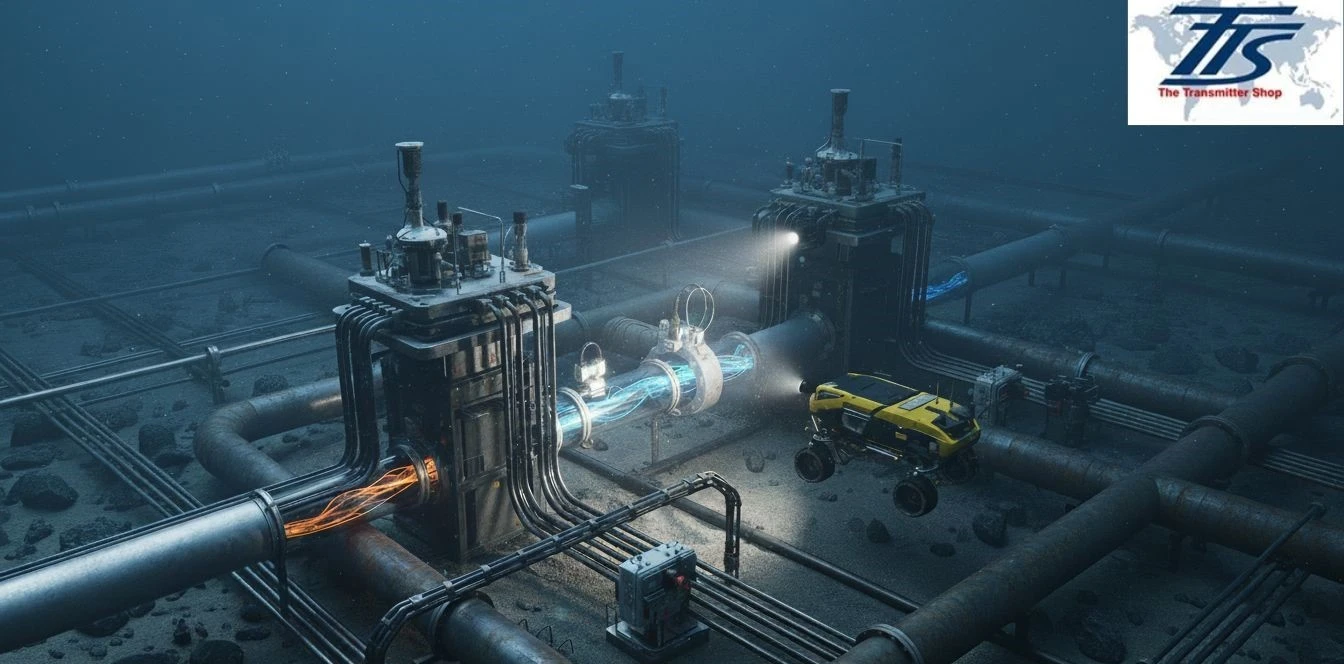

As oil and gas companies move further offshore, subsea operations have become central to global energy production. Extracting hydrocarbons from beneath the ocean floor requires robust systems that can withstand extreme conditions. Among these, accurate flow measurement is one of the most critical functions.

Reliable measurement of oil, gas and water flows ensures production efficiency, regulatory compliance and equipment integrity. Yet, the subsea environment introduces unique technical and operational challenges. In this blog, we explore flow measurement challenges in subsea operations, why they matter and how modern technologies including advanced flow transmitters are helping overcome them.

Why Flow Measurement Matters in Subsea Operations

Unlike surface facilities where systems are more accessible, subsea flow measurement must work under harsher, less predictable conditions. Its importance extends across several domains:

- Production Optimization: Accurate measurement helps balance production rates between wells, minimize water cut and maximize hydrocarbon yield.

- Reservoir Management: Flow data provides reservoir engineers with critical insights into reservoir depletion, fluid properties and injection efficiency.

- Safety & Environmental Compliance: Misreading flows can lead to over-pressurization, pipeline leaks, or spills events with severe consequences in deepwater environments.

- Cost Efficiency: Early detection of anomalies prevents unplanned shutdowns and reduces the need for costly offshore interventions.

Key Flow Measurement Challenges in Subsea Operations

High Pressure and Extreme Depths

Subsea equipment often operates at depths exceeding 3,000 meters, where pressures surpass 15,000 psi. Sensors and transmitters must withstand these stresses without losing calibration or functionality.

-

Issue: Sensor drift, seal failures, or material fatigue.

-

Impact: Reduced data accuracy and shorter equipment lifespan.

Multiphase Flow Complexity

In subsea wells, fluids rarely flow as pure oil or gas. Instead, operators face a mixture of oil, natural gas, water, and sometimes sand. These phases shift under changing pressure and temperature conditions, making real-time flow measurement difficult.

- Issue: Distinguishing between phases without separation equipment.

- Impact: Errors in production allocation, reservoir modelling and custody transfer.

Limited Accessibility for Maintenance

Subsea meters are installed on the seabed, often hundreds of kilometres offshore. Access requires remotely operated vehicles (ROVs), divers, or intervention vessels.

- Issue: Calibration or repair requires major effort.

- Impact: Long downtimes and high costs for even minor issues.

Corrosion and Material Degradation

Subsea flow meters face constant exposure to seawater, high salinity and erosion, and injected chemicals. Even corrosion-resistant alloys eventually degrade.

- Issue: Reduced sensor accuracy and unexpected failures.

- Impact: Increased risk of system downtime and costly replacements.

Power and Data Transmission Constraints

Reliable subsea operations require continuous power and uninterrupted communication with topside control systems. Yet, long subsea cables are prone to degradation or damage.

-

Issue: Loss of real-time flow data transmission.

-

Impact: Delayed decision-making and safety hazards.

Calibration and Verification Issues

Traditional recalibration methods are not feasible subsea. Operators rely on computational models, redundancy, or topside comparisons to validate measurements.

-

Issue: Calibration drift over time without physical adjustments.

-

Impact: Long-term loss of measurement integrity.

Solutions and Emerging Technologies

The industry is responding with innovations to counter subsea challenges:

- Subsea Multiphase Flow Meters (MPFMs): Accurately measure oil, gas and water fractions simultaneously.

- High-Grade Alloys & Coatings: Materials like Inconel and titanium extend equipment life against corrosion.

- Digital Twins: Virtual models replicate flow meter performance, aiding recalibration and predictive analytics.

- Fiber Optic Sensing: Provides continuous, real-time data with high sensitivity.

- Remote Monitoring & AI: Enables predictive maintenance, reducing unplanned interventions.

At The Transmitter Shop, you’ll find pressure, differential pressure, and flow transmitters that integrate into advanced systems for enhanced subsea monitoring and control.

Which Flow Transmitters Are Used in Subsea Operations?

Choosing the right flow transmitter is critical to ensure accuracy and reliability in subsea environments. Since conditions involve high pressure, multiphase flows and corrosion risks, operators typically rely on:

- Differential Pressure (DP) Flow Transmitters - Widely used with orifice plates, Venturi tubes, or wedge meters to measure flow under extreme subsea pressures. They are known for robustness and long-term reliability.

- Coriolis Flow Transmitters - Preferred for accurate mass flow measurement and density monitoring, especially in multiphase or slurry-type flows.

- Ultrasonic Flow Transmitters - Suitable for non-intrusive measurement of subsea pipelines, offering high accuracy without requiring pipe penetration.

- Multiphase Flow Meters (MPFMs) - Advanced solutions that measure oil, gas and water fractions simultaneously in real time, making them ideal for complex subsea production wells.

Each type of transmitter is selected based on the fluid composition, pressure conditions and desired accuracy. For example, differential pressure transmitters are often chosen for their proven reliability in deepwater projects, while Coriolis meters are favored when precise multiphase flow data is essential.

You can explore a range of high-performance flow transmitters from leading brands at The Transmitter Shop, designed to deliver reliable performance even under demanding offshore conditions.

Best Practices for Reliable Subsea Flow Measurement

- Use flow meters designed for HPHT (high-pressure, high-temperature) environments.

- Dual or backup meters prevent data loss during failures.

- Use AI-driven analytics to detect early signs of degradation.

- Compare subsea measurements with topside data to detect anomalies.

- Choose transmitters built with corrosion- and erosion-resistant materials.

Many offshore operators prefer proven Rosemount pressure transmitters and other trusted brands available at The Transmitter Shop for reliability under harsh conditions.

Conclusion

Flow measurement in subsea operations is one of the most demanding engineering challenges in the oil and gas industry. With high pressures, multiphase flows, corrosive environments and accessibility issues, achieving accurate and reliable measurements requires advanced technology and best practices.

Thanks to innovations like multiphase flow meters, fiber optic sensing, and digital twin calibration, operators can now maintain precision even in the most unforgiving subsea environments.

For businesses looking to enhance their measurement reliability, investing in high-quality pressure and flow transmitters from trusted brands is a proven step toward safer, more efficient subsea operations.

Related Posts

- What are the Steps Involved in Calibrating Pressure Gauge?

- All Important Questions on Reconditioned Transmitters Answered

- Is Remanufactured Transmitter a Better Option than a New One?

- Differential Pressure Transmitters: How Do They Help in Flow Measurements?

- 3 Whats that Explain How Often You Should Calibrate Pressure Transducer

- Guidelines for Troubleshooting Pressure Transducers

- Learn How to Calibrate a Pressure Transmitter – II

- Learn How to Calibrate a Pressure Transmitter

- Know Three Interesting Uses of Pressure Transmitters

- Things to Check before Buying a New Pressure Transmitter

- A Look at Various Types of Industrial Transmitters – Part II

- A Look at Various Types of Industrial Transmitters Part I

- All Questions on Smart Transmitters and their Calibration Answered

- 3 Major Pressure Transmitter Technologies That Made the Device Popular

- An Unconventional Guide to Selecting the Right Pressure Sensor

- Factors To Be Considered While Differentiating $40 and $400 Pressure Transmitters

- Tips to Augment the Performance and Service Life of Pressure Transmitter

- Factors of Consideration When Choosing Pressure Transmitters

- 5 Most Popular Pressure Transmitter Technologies

- Tips to Improve the Performance of Pressure Sensors

- Factors to Consider When Choosing a Pressure Transmitter Manifold

- Safety Tips for Differential Pressure Transmitter Operation

- Impact of Shock and Vibration on Pressure Transducer

- Rosemount 3051S vs 3051C Transmitter – What is Your Choice?

- Rosemount 2088 Vs Rosemount 3051 – A Few Points of Differences Discussed

- Difference in Conventional Transmitters and Smart Transmitters

- How to Choose Diaphragm Seals for Your Application?

- How to Select Pressure Transmitter for Your Application?

- Remote Seals: Significance, Working Principle & Applications

- How Do You Calibrate A Flow Transmitter?

- What is Absolute Pressure Transmitter & how does it work?

- HART Communication Protocol: Overview, Working Principle, Benefits in Industrial Automation

- Absolute and Gauge Pressure Transmitters - Overview and Working Principle

- Flow Meter vs Flow Transmitter: Know the Difference

- How Do You Test for 4 to 20mA Signal in a Pressure Transmitter?

- Multivariable Transmitter: What Is It and How Does It Work?

- Pressure Transmitters vs. Pressure Transducers: Learn the Differential Characteristics

- Procedure to Calculate Accuracy of Pressure Transmitter Discussed

- Testing Pressure Gauges: Processes of Verification Test and Functional Test

- An Ultimate Selection Guide for Flow Transmitters

- The Benefits and Challenges of HVAC System Balancing

- Fluid Flow Isolation Techniques for Pressure Instrumentation

- Understanding Pressure Ranges and Units for Fluid System Monitoring

- Understanding the Impact of Pressure Fluctuations on Drying Performance

- Monitoring and Controlling Energy Production in Power Plants

- Common Challenges in Air Flow Measurement and How to Overcome Them

- Pressure Monitoring in Pump Systems: A Comprehensive Guide

- Exploring Density and Viscosity Measurement in Industrial Processes

- Pneumatic Pressure Controllers: A Safe Choice for Hazardous Areas

- A Practical Guide to Vacuum Measurement and Operation

- 4-20 mA Transmitter Wiring: Understanding 2-Wire, 3-Wire, and 4-Wire Systems

- Flow Measurement Challenges in Subsea Operations

- Flow Measurement Challenges in Subsea Operations

- Pressure Sensing Sensor Modes of Measurement Key Differences and Benefits

- Electromagnetic Flow Sensors for Abrasive and Corrosive Fluids

- Mass Flow Meters and Their Working Principles

- Best Explosion Proof Switches for Hazardous Environments

- Best Explosion Proof Switches for Hazardous Environments

- Furnace Flame Sensor Faults Everything You Need to Know for Safe Operation

- Pneumatic Pressure Controllers: A Safe Choice for Hazardous Areas

- A Practical Guide to Vacuum Measurement and Operation

- Understanding Electrochemical Detection: Principles, Techniques and Environmental Application

QUICK ENQUIRY