What are the Steps Involved in Calibrating Pressure Gauge?

Brian Craig

March 15, 2018

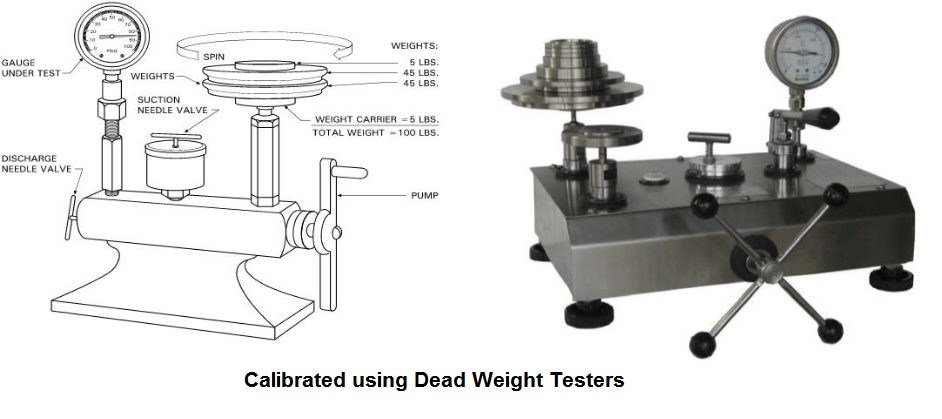

Today, a variety of transmitters are being used to measure parameters, such as temperature, pressure, flow, level, etc. An instrument, which is used to measure the pressure of a fluid is referred as a pressure gauge. These gauges are used in several industries. However, for an accurate reading of the fluid pressure, these instruments require proper calibration. Now, you can calibrate the instrument by using diverse tools, or methods. Yet, the most widely used method is by using the dead weight tester. What is this tester? How these pressure gauges are calibrated using dead weight testers? Are you eager to find out? Please read the following post, which explains the calibration process, in steps.

What is a Dead Weight Tester?

First things first. To understand the calibration process, you first need to know what a dead weight tester actually is. In simple words, it is basically an apparatus, which uses calibrated weights. These weights help check whether the readings shown by the pressure gauges are accurate or not. Fluid, connection port, and a weight and piston are the main components of these testers. The reference pressure of these testers is calculated by the formula –

p = F / A

Where,

- p: Reference Pressure (Pa)

- F: Force applied to the Piston (N)

- A: Area PCU (m2)

How is Pressure Gauge Calibrated Using Dead Weight Tester?

To calibrate a pressure gauge using dead weight tester assembly requires one to follow certain steps for a precise calibration. The steps involved in the calibration process are as follows:

- Step 1: Making the Arrangements

This is the very first step of the entire process. Before you start the calibration of pressure gauges, make sure that the device is placed at a uniform level. The workbench should be stable for proper operation. Once you ensure this, attach the pressure gauge to the test port.

- Step 2: Fixing the Zero Error

You do not want zero error to peek in while calibrating the gauge. Thus, it is advisable to confirm zero reading on the pressure gauge. Adjust the gauge, so that it is reading zero. If this is not done, then the gauge might get calibrated with some zero error still present.

- Step 3: Placement of the Weight

This is the step, from which the actual calibration begins. Select a reference weight, and keep it on the vertical piston of the dead weight tester assembly.

- Step 4: Moving the Piston

Other than the vertical piston, there is one more piston – a horizontal one. Turn the handle attached to this piston. Do this, until a point is reached, where the piston and the weight are freely supported by oil. Now, turn the vertical piston, so that it starts floating freely.

- Step 5: Recording the Readings

Let the system stabilize for some time. Now, once the system gets properly stabilized, it is the right time to record the reading of the gauge and weight.

- Step 6: The Final Step

This is the final step of calibration. Follow the steps 3 through step 5, and go on applying pressure. Do not stop until maximum pressure is reached. Now, go on reducing the weights one by one till the point the gauge pressure reads zero. Check whether there is an error in the gauge pressure reading. If the error is within the accuracy limits, then there is no need to worry. Your gauge is calibrated successfully.

A wide range of pressure measuring devices can be calibrated using these dead weight testers. You can easily calibrate industrial pressure gauges, and pressure transmitters with these testers. To know more about pressure gauges, and their calibration, you can get in touch with the experts. The Transmitter Shop is one such experienced player, which can help you calibrate your pressure gauges with great accuracy.

Related Posts

- What are the Steps Involved in Calibrating Pressure Gauge?

- All Important Questions on Reconditioned Transmitters Answered

- Is Remanufactured Transmitter a Better Option than a New One?

- Differential Pressure Transmitters: How Do They Help in Flow Measurements?

- 3 Whats that Explain How Often You Should Calibrate Pressure Transducer

- Guidelines for Troubleshooting Pressure Transducers

- Learn How to Calibrate a Pressure Transmitter – II

- Learn How to Calibrate a Pressure Transmitter

- Know Three Interesting Uses of Pressure Transmitters

- Things to Check before Buying a New Pressure Transmitter

- A Look at Various Types of Industrial Transmitters – Part II

- A Look at Various Types of Industrial Transmitters Part I

- All Questions on Smart Transmitters and their Calibration Answered

- 3 Major Pressure Transmitter Technologies That Made the Device Popular

- An Unconventional Guide to Selecting the Right Pressure Sensor

- Factors To Be Considered While Differentiating $40 and $400 Pressure Transmitters

- Tips to Augment the Performance and Service Life of Pressure Transmitter

- Factors of Consideration When Choosing Pressure Transmitters

- 5 Most Popular Pressure Transmitter Technologies

- Tips to Improve the Performance of Pressure Sensors

- Factors to Consider When Choosing a Pressure Transmitter Manifold

- Safety Tips for Differential Pressure Transmitter Operation

- Impact of Shock and Vibration on Pressure Transducer

- Rosemount 3051S vs 3051C Transmitter – What is Your Choice?

- Rosemount 2088 Vs Rosemount 3051 – A Few Points of Differences Discussed

- Difference in Conventional Transmitters and Smart Transmitters

- How to Choose Diaphragm Seals for Your Application?

- How to Select Pressure Transmitter for Your Application?

- Remote Seals: Significance, Working Principle & Applications

- How Do You Calibrate A Flow Transmitter?

- What is Absolute Pressure Transmitter & how does it work?

- HART Communication Protocol: Overview, Working Principle, Benefits in Industrial Automation

- Absolute and Gauge Pressure Transmitters - Overview and Working Principle

- Flow Meter vs Flow Transmitter: Know the Difference

- How Do You Test for 4 to 20mA Signal in a Pressure Transmitter?

- Multivariable Transmitter: What Is It and How Does It Work?

- Pressure Transmitters vs. Pressure Transducers: Learn the Differential Characteristics

- Procedure to Calculate Accuracy of Pressure Transmitter Discussed

- Testing Pressure Gauges: Processes of Verification Test and Functional Test

- An Ultimate Selection Guide for Flow Transmitters

- The Benefits and Challenges of HVAC System Balancing

- Fluid Flow Isolation Techniques for Pressure Instrumentation

- Understanding Pressure Ranges and Units for Fluid System Monitoring

- Understanding the Impact of Pressure Fluctuations on Drying Performance

- Monitoring and Controlling Energy Production in Power Plants

- Common Challenges in Air Flow Measurement and How to Overcome Them

- Pressure Monitoring in Pump Systems: A Comprehensive Guide

- Exploring Density and Viscosity Measurement in Industrial Processes

- Pneumatic Pressure Controllers: A Safe Choice for Hazardous Areas

- A Practical Guide to Vacuum Measurement and Operation

- 4-20 mA Transmitter Wiring: Understanding 2-Wire, 3-Wire, and 4-Wire Systems

- Flow Measurement Challenges in Subsea Operations

- Flow Measurement Challenges in Subsea Operations

- Pressure Sensing Sensor Modes of Measurement Key Differences and Benefits

- Electromagnetic Flow Sensors for Abrasive and Corrosive Fluids

- Mass Flow Meters and Their Working Principles

- Best Explosion Proof Switches for Hazardous Environments

- Best Explosion Proof Switches for Hazardous Environments

- Furnace Flame Sensor Faults Everything You Need to Know for Safe Operation

- Pneumatic Pressure Controllers: A Safe Choice for Hazardous Areas

- A Practical Guide to Vacuum Measurement and Operation

- Understanding Electrochemical Detection: Principles, Techniques and Environmental Application

QUICK ENQUIRY