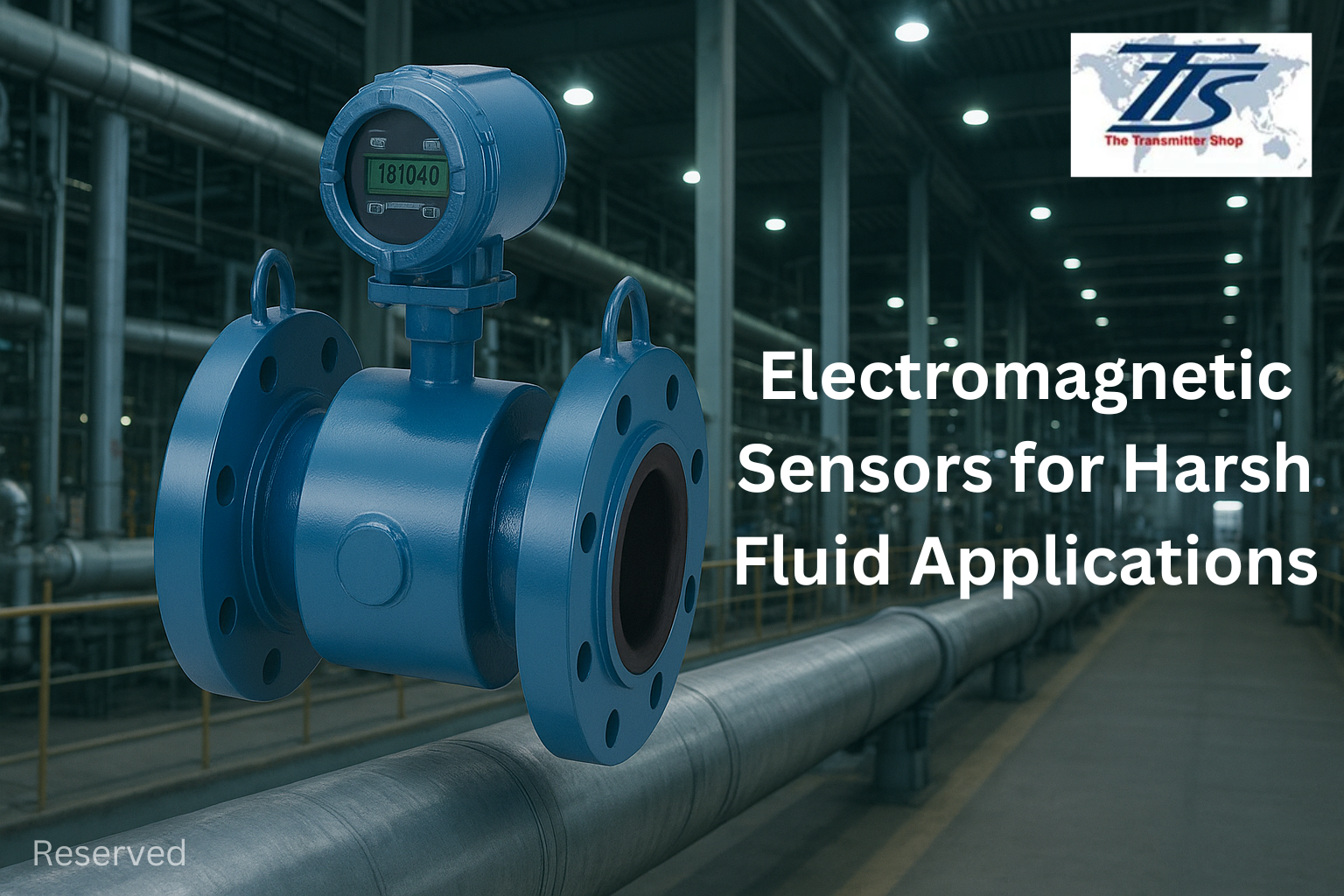

Electromagnetic Flow Sensors for Abrasive and Corrosive Fluids

Brian Craig

August 22, 2025

Handling abrasive slurries or corrosive liquids is one of the toughest challenges in industrial flow measurement. Conventional mechanical meters often fail in such environments due to wear, clogging, or chemical attack. That’s why many industries rely on electromagnetic flow meters, also known as magnetic flow meters or mag meters, for reliable, long-term performance.

Whether you’re dealing with wastewater chemicals, mining slurries, or aggressive acids, an electromagnetic flow sensor provides accurate and maintenance-free measurement. In this article, we’ll explore how these devices work, why they’re ideal for harsh fluids, and what manufacturers should consider when sourcing the right solution.

How Electromagnetic Flow Sensors Work

An electromagnetic flow meter operates on Faraday’s Law of Electromagnetic Induction. When a conductive liquid flows through a pipe equipped with a magnetic field, a voltage is generated. The electromagnetic flow sensor detects this voltage, and an electromagnetic flow transmitter converts it into a flow rate reading.

Unlike traditional meters, a mag meter flow meter has:

- No moving parts, which eliminates wear and tear.

- Non-intrusive measurement, so the fluid doesn’t contact sensitive components.

- Versatility, since it can measure almost any conductive liquid, even those with suspended solids.

This makes the electromagnetic meter one of the most reliable technologies for abrasive and corrosive applications.

Challenges in Measuring Abrasive and Corrosive Fluids

Industrial plants often deal with fluids that damage conventional meters. Common challenges include:

- Abrasive fluids: Slurries, mining tailings, sand-laden wastewater, pulp and paper mixtures, all of which grind down mechanical parts.

- Corrosive fluids: Acids, alkalis, chemical byproducts, and caustic cleaning solutions that corrode standard materials.

- High maintenance costs: Frequent repairs and recalibration due to wear.

- Inaccurate measurement: Sediment buildup or corrosion reduces meter reliability.

This is where magnetic flow meters excel, delivering accuracy and longevity in conditions that destroy other technologies.

Why Electromagnetic Flow Meters Are Ideal for Harsh Fluids

Electromagnetic flow sensors stand out because they’re designed to handle aggressive liquids without losing accuracy. Key advantages include:

- No mechanical obstructions - eliminates clogging and abrasion issues.

- Durable lining options - PTFE, PFA, ceramic, or rubber protect against both corrosion and erosion.

- Corrosion-resistant electrodes - Hastelloy, tantalum, or platinum withstand chemical attack.

- High accuracy - maintains ±0.2–0.5% accuracy even with slurries or corrosive solutions.

- Smart transmitters - modern electromagnetic flow transmitters offer diagnostics, digital outputs (HART, Modbus, Profibus), and IoT connectivity for real-time monitoring.

In short, a mag meter flow meter combines rugged construction with advanced electronics to ensure accurate, long-term performance in abrasive and corrosive service.

Key Design Considerations for Harsh Fluid Applications

When selecting an electromagnetic water meter or magnetic flow sensor for abrasive/corrosive conditions, material selection is critical:

- Lining materials:

- PTFE/PFA - best for strong acids and alkalis.

- Ceramic - highly resistant to abrasion and erosion.

- Rubber - cost-effective for slurries and wastewater.

- Electrode materials:

- Stainless Steel - general-purpose, cost-effective.

- Hastelloy - excellent for chemical and corrosive applications.

- Tantalum or Platinum - resistant to highly aggressive acids.

- Protective coatings: Extend sensor life in abrasive environments.

- Signal processing: Smart electromagnetic flow transmitters reduce noise and enhance accuracy.

Industries Using Electromagnetic Flow Meters in Harsh Conditions

Electromagnetic flow technology is trusted across multiple sectors where abrasive or corrosive fluids are common:

- Mining & Minerals - slurries, ore tailings, abrasive suspensions.

- Chemical & Petrochemical - acids, solvents, alkalis, and corrosive byproducts.

- Water & Wastewater - sludge, grit, and chemical dosing.

- Food & Beverage - caustic cleaning-in-place (CIP) solutions.

- Pulp & Paper - fiber suspensions and abrasive fillers.

- Power Generation - cooling water with impurities, chemical treatment fluids.

By choosing the right electromagnetic meter, industries ensure accuracy, reduce downtime, and extend equipment life.

Best Practices for Long-Term Reliability

To maximize performance, consider these best practices:

- Correct installation - Ensure proper grounding and straight pipe runs.

- Choose the right lining/electrode materials for your specific fluid.

- Schedule regular calibration of the electromagnetic flow transmitter.

- Leverage smart diagnostics for predictive maintenance.

- Prevent buildup - periodic inspection of lining and electrodes.

Choosing the Right Supplier

Since electromagnetic flow meters are critical to process efficiency, sourcing from a trusted manufacturer or distributor is key. Look for:

- Industry certifications (ISO, CE, ATEX).

- Proven expertise in corrosive/abrasive applications.

- Availability of spare parts, calibration services, and support.

- Strong track record with industrial clients.

Selecting the right partner ensures your magnetic flow meter performs reliably for years.

Conclusion

When it comes to measuring abrasive and corrosive fluids, traditional meters simply don’t hold up. An electromagnetic flow meter (mag meter flow meter) offers a durable, accurate, and cost-effective solution with no moving parts and customizable materials. Whether you call it a magnetic flow sensor, electromagnetic water meter, or electromagnetic flow transmitter, the principle is the same, reliable flow measurement under the toughest conditions.

Looking for the right electromagnetic flow sensor for your application? Contact our team today for expert guidance in selecting a solution tailored to your process.

Related Posts

- Important Calibration Tips for Pressure Sensors

- What is RTD Sensor and How Does it Work?

- What is a Thermocouple and How Does It Work?

- Why Platinum is a Preferred Choice in RTD Sensors?

- How to Choose the Right Exhaust Gas Temperature Sensor for Your Engine

- Role of Sensors in the Food Processing Plant

- How Can Greenhouse Gas Emissions Be Reduced?

- Understanding Electrochemical Detection: Principles, Techniques and Environmental Application

- Furnace Flame Sensor Faults: Everything You Need to Know for Safe Operation

- Complete Hydrogen Gas Safety and Measurement Solutions

- Key Sensors for Monitoring Emissions in Wet and Dry Scrubber Systems

- What is a Mass Flow Meter? Working Principles and Key Benefits

- Electromagnetic Flow Sensors for Abrasive and Corrosive Fluids

- Pressure Sensing Sensor Modes of Measurement: Key Differences and Benefits

- Flow Measurement Challenges in Subsea Operations

- Pressure Sensing Sensor Modes of Measurement Key Differences and Benefits

- Electromagnetic Flow Sensors for Abrasive and Corrosive Fluids

- Mass Flow Meters and Their Working Principles

- Best Explosion Proof Switches for Hazardous Environments

- Best Explosion Proof Switches for Hazardous Environments

- Furnace Flame Sensor Faults Everything You Need to Know for Safe Operation

- Pneumatic Pressure Controllers: A Safe Choice for Hazardous Areas

- A Practical Guide to Vacuum Measurement and Operation

- Understanding Electrochemical Detection: Principles, Techniques and Environmental Application

QUICK ENQUIRY