What is Absolute Pressure Transmitter & how does it work?

Brian Craig

August 25, 2020

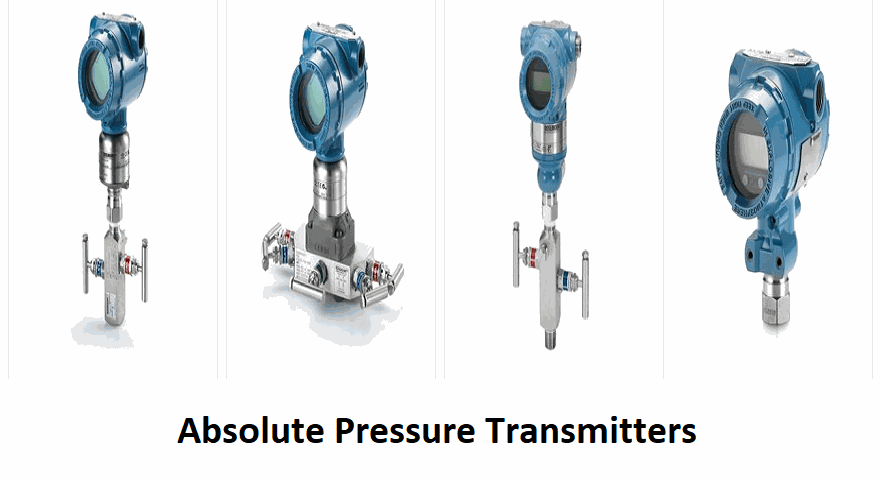

Pressure transmitters often referred to as pressure transducers, are designed to measure the pressure of gases and liquids used in process industries. As technology is developing rapidly, these transmitters have also evolved with a lot of technological advancements and features. Primarily, they were equipped with capacitance and piezo-resistive technologies. Today, they feature various microprocessor-based technologies, thus hailed as smart pressure transmitters, which are being widely used today. Among them, absolute pressure transmitters are the most commonly required ones.

What is Absolute Pressure Transmitter?

Absolute pressure transmitter measures pressure in a complete vacuum with no contents inside. The measurement taken in absolute pressure uses absolute zero as the reference point. So, here there is no comparison in terms of pressure changes or relativity. With such importance in many industrial processes, it is essential to understand the pressure transmitter working principle along with their applications. This post discusses the same.

How Does an Absolute Pressure Transmitter Work?

With absolute pressure transmitters, the pressure is measured relative to a perfect vacuum. This mean, they are not influenced by any external atmospheric change including altitude or air pressure variations. As they do not have any connection with the external system, there is no release node in the system. Simply, the side of the absolute pressure transmitter which is not in contact with the pressure media is being exposed to a permanently sealed vacuum chamber. These transmitters convert pressure or mechanical energy into electrical signals. Transmitters with absolute zero pressure are used as the part of elevation or barometric related pressure estimations.

What are the Applications of Absolute Pressure Transmitter?

Absolute pressure transmitters are used to measure temperature, pressure, gases, and flowrate in closed systems across industries. The following are some industries where pressure sensors are widely used:

- The absolute pressure transmitter is widely used wherever elevation above altimeter measurement is required, such as navigation systems.

- Nowadays, these transmitters are also contributing to the weather forecasting field for barometric measurements. They allow weather stations to be miniaturized. For instance, one can forecast the weather using tiny sensors in smartphones or tablets.

- Most of the industrial applications demand a partial vacuum. This applies in case of food packaging systems, where residual pressure determines the life of the inside product. The absolute pressure sensor helps ensure the same pressure in each package.

- Absolute pressure transmitters are also used in the automation industry. In petrol and diesel vehicles, they are used for measuring the pressure in the engine manifold. Thus, they are known as manifold absolute pressure or MAP sensors. The engine’s electronic control unit (abbreviated as ECU) uses this information to fix optimal combustion of the ignition timing and air-fuel mix.

In addition to this, they are used in industries like pharmaceuticals, chemicals, science research, and more.

Are you looking for an absolute pressure transmitter for your industrial application? If yes, then it is important to source them from a reliable supplier like The Transmitter Shop. The company offers you appropriately designed pressure sensors from recognized brands such as Emerson. Their inventory consists of a variety of pressure transmitter models. Contact us today to solve your specific queries about absolute pressure transmitters.

Related Posts

- What are the Steps Involved in Calibrating Pressure Gauge?

- All Important Questions on Reconditioned Transmitters Answered

- Is Remanufactured Transmitter a Better Option than a New One?

- Differential Pressure Transmitters: How Do They Help in Flow Measurements?

- 3 Whats that Explain How Often You Should Calibrate Pressure Transducer

- Guidelines for Troubleshooting Pressure Transducers

- Learn How to Calibrate a Pressure Transmitter – II

- Learn How to Calibrate a Pressure Transmitter

- Know Three Interesting Uses of Pressure Transmitters

- Things to Check before Buying a New Pressure Transmitter

- A Look at Various Types of Industrial Transmitters – Part II

- A Look at Various Types of Industrial Transmitters Part I

- All Questions on Smart Transmitters and their Calibration Answered

- 3 Major Pressure Transmitter Technologies That Made the Device Popular

- An Unconventional Guide to Selecting the Right Pressure Sensor

- Factors To Be Considered While Differentiating $40 and $400 Pressure Transmitters

- Tips to Augment the Performance and Service Life of Pressure Transmitter

- Factors of Consideration When Choosing Pressure Transmitters

- 5 Most Popular Pressure Transmitter Technologies

- Tips to Improve the Performance of Pressure Sensors

- Factors to Consider When Choosing a Pressure Transmitter Manifold

- Safety Tips for Differential Pressure Transmitter Operation

- Impact of Shock and Vibration on Pressure Transducer

- Rosemount 3051S vs 3051C Transmitter – What is Your Choice?

- Rosemount 2088 Vs Rosemount 3051 – A Few Points of Differences Discussed

- Difference in Conventional Transmitters and Smart Transmitters

- How to Choose Diaphragm Seals for Your Application?

- How to Select Pressure Transmitter for Your Application?

- Remote Seals: Significance, Working Principle & Applications

- How Do You Calibrate A Flow Transmitter?

- What is Absolute Pressure Transmitter & how does it work?

- HART Communication Protocol: Overview, Working Principle, Benefits in Industrial Automation

- Absolute and Gauge Pressure Transmitters - Overview and Working Principle

- Flow Meter vs Flow Transmitter: Know the Difference

- How Do You Test for 4 to 20mA Signal in a Pressure Transmitter?

- Multivariable Transmitter: What Is It and How Does It Work?

- Pressure Transmitters vs. Pressure Transducers: Learn the Differential Characteristics

- Procedure to Calculate Accuracy of Pressure Transmitter Discussed

- Testing Pressure Gauges: Processes of Verification Test and Functional Test

- An Ultimate Selection Guide for Flow Transmitters

- The Benefits and Challenges of HVAC System Balancing

- Fluid Flow Isolation Techniques for Pressure Instrumentation

- Understanding Pressure Ranges and Units for Fluid System Monitoring

- Understanding the Impact of Pressure Fluctuations on Drying Performance

- Monitoring and Controlling Energy Production in Power Plants

- Common Challenges in Air Flow Measurement and How to Overcome Them

- Pressure Monitoring in Pump Systems: A Comprehensive Guide

- Exploring Density and Viscosity Measurement in Industrial Processes

- Pneumatic Pressure Controllers: A Safe Choice for Hazardous Areas

- A Practical Guide to Vacuum Measurement and Operation

- Complete Hydrogen Gas Safety and Measurement Solutions

- Steam Boiler Drum Level Measurement A Comparison of Control System Technologies

- Furnace Flame Sensor Faults Everything You Need to Know for Safe Operation

- Comparison between Multi Valve Manifolds Block Valves and Bleed Valves

- Pneumatic Pressure Controllers: A Safe Choice for Hazardous Areas

- Furnace Flame Sensor Faults Everything You Need to Know for Safe Operation

- Pneumatic Pressure Controllers: A Safe Choice for Hazardous Areas

- How Can Greenhouse Gas Emissions Be Reduced?

- A Practical Guide to Vacuum Measurement and Operation

- Understanding Electrochemical Detection: Principles, Techniques and Environmental Application

QUICK ENQUIRY