3 Major Pressure Transmitter Technologies That Made the Device Popular

Brian Craig

September 04, 2018

Pressure transmitters, which are also commonly referred to as pressure transducers, are the devices, which are used to convert pressure into an electrical signal. This signal can then be used to drive further circuitry. Over the years, these transmitters have seen a lot of developments, and technological advancements. There are a variety of pressure transmitters being used today, and each type has its own set of properties, and features. These process control devices are dominating the market for past several years, and are expected to continue their dominance in the upcoming years, due to the novel trends in the pressure transmitter technology. What are these trends? Read the following post to know them.

What are the Different Key Technologies of Pressure Transmitters?

Pressure transmitters are being used for many years for various applications. However, the following 3 technological trends of these devices are among the major reasons for their increasing popularity.

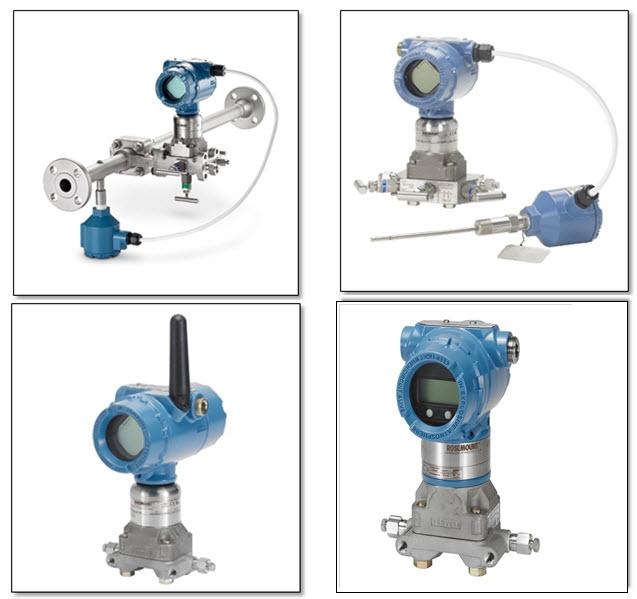

- Wireless Pressure Transmitters- This is one of the major trends in the pressure transmitter technology. As their name suggests, the wireless pressure transmitters, do not use wires. This allows one to install them in hard-to-reach locations. As the cost of wire runs is eliminated, these transmitters can be installed at a lower installation cost as compared to the other.

These transmitters find their use in a vast range of applications, which include:

- Pump Monitoring

- Water Tank Level Monitoring

- Wastewater Monitoring

- Hydraulic Systems Monitoring

- Leakage Monitoring

- Multivariable Pressure Transmitters - As their name implies, the multivariable transmitters are capable of measuring more than one process variables. You can measure variables, such as temperature, pressure, mass, volumetric and energy flow, and differential pressure with these devices. Thus, you can replace three single variable transmitters with one multivariable transmitter. These devices are known to enhance the process insight and accuracy, and hence the performance.

They are most commonly used in the following applications:

- Liquid Measurement

- Measurement of Gas & Natural Gas

- Saturated & Superheated Steam Measurement

- Integrated Pressure Transmitters - This is yet another trend that has driven the pressure transmitter market growth. In this type of transmitter, a flow element is integrated with the multivariable pressure transmitter. This facilitates a complete multivariable flowmeter. In these transmitters, a primary element is mounted on them. The flowmeter of these transducers is calibrated with the primary element. What makes it special is that a user is not required to buy the primary flow element (flow nozzle or orifice plate), and the differential pressure transmitter from two different suppliers.

All the three trends explained above are among the major reasons that led to the growth of pressure transmitter market. Moreover, the aforementioned transmitters are capable of delivering precise and optimal performance. So, if you are looking out for pressure transmitters for your industrial applications, then consider from those explained above. You can also discuss it with the experts, before making the selection of the transducer. Also, sourcing these devices from well-known and trusted manufacturers goes a long way into deciding the performance of the transmitters. The Transmitter Shop is one such leading, and experienced manufacturer and supplier of industry-grade pressure transmitters in the US.

Related Posts

- What are the Steps Involved in Calibrating Pressure Gauge?

- All Important Questions on Reconditioned Transmitters Answered

- Is Remanufactured Transmitter a Better Option than a New One?

- Differential Pressure Transmitters: How Do They Help in Flow Measurements?

- 3 Whats that Explain How Often You Should Calibrate Pressure Transducer

- Guidelines for Troubleshooting Pressure Transducers

- Learn How to Calibrate a Pressure Transmitter – II

- Learn How to Calibrate a Pressure Transmitter

- Know Three Interesting Uses of Pressure Transmitters

- Things to Check before Buying a New Pressure Transmitter

- A Look at Various Types of Industrial Transmitters – Part II

- A Look at Various Types of Industrial Transmitters Part I

- All Questions on Smart Transmitters and their Calibration Answered

- 3 Major Pressure Transmitter Technologies That Made the Device Popular

- An Unconventional Guide to Selecting the Right Pressure Sensor

- Factors To Be Considered While Differentiating $40 and $400 Pressure Transmitters

- Tips to Augment the Performance and Service Life of Pressure Transmitter

- Factors of Consideration When Choosing Pressure Transmitters

- 5 Most Popular Pressure Transmitter Technologies

- Tips to Improve the Performance of Pressure Sensors

- Factors to Consider When Choosing a Pressure Transmitter Manifold

- Safety Tips for Differential Pressure Transmitter Operation

- Impact of Shock and Vibration on Pressure Transducer

- Rosemount 3051S vs 3051C Transmitter – What is Your Choice?

- Rosemount 2088 Vs Rosemount 3051 – A Few Points of Differences Discussed

- Difference in Conventional Transmitters and Smart Transmitters

- How to Choose Diaphragm Seals for Your Application?

- How to Select Pressure Transmitter for Your Application?

- Remote Seals: Significance, Working Principle & Applications

- How Do You Calibrate A Flow Transmitter?

- What is Absolute Pressure Transmitter & how does it work?

- HART Communication Protocol: Overview, Working Principle, Benefits in Industrial Automation

- Absolute and Gauge Pressure Transmitters - Overview and Working Principle

- Flow Meter vs Flow Transmitter: Know the Difference

- How Do You Test for 4 to 20mA Signal in a Pressure Transmitter?

- Multivariable Transmitter: What Is It and How Does It Work?

- Pressure Transmitters vs. Pressure Transducers: Learn the Differential Characteristics

- Procedure to Calculate Accuracy of Pressure Transmitter Discussed

- Testing Pressure Gauges: Processes of Verification Test and Functional Test

- An Ultimate Selection Guide for Flow Transmitters

- The Benefits and Challenges of HVAC System Balancing

- Fluid Flow Isolation Techniques for Pressure Instrumentation

- Understanding Pressure Ranges and Units for Fluid System Monitoring

- Understanding the Impact of Pressure Fluctuations on Drying Performance

- Monitoring and Controlling Energy Production in Power Plants

- Common Challenges in Air Flow Measurement and How to Overcome Them

- Pressure Monitoring in Pump Systems: A Comprehensive Guide

- Exploring Density and Viscosity Measurement in Industrial Processes

- Pneumatic Pressure Controllers: A Safe Choice for Hazardous Areas

- A Practical Guide to Vacuum Measurement and Operation

- Complete Hydrogen Gas Safety and Measurement Solutions

- Steam Boiler Drum Level Measurement A Comparison of Control System Technologies

- Furnace Flame Sensor Faults Everything You Need to Know for Safe Operation

- Comparison between Multi Valve Manifolds Block Valves and Bleed Valves

- Pneumatic Pressure Controllers: A Safe Choice for Hazardous Areas

- Furnace Flame Sensor Faults Everything You Need to Know for Safe Operation

- Pneumatic Pressure Controllers: A Safe Choice for Hazardous Areas

- How Can Greenhouse Gas Emissions Be Reduced?

- A Practical Guide to Vacuum Measurement and Operation

- Understanding Electrochemical Detection: Principles, Techniques and Environmental Application

QUICK ENQUIRY