- Transducer

- Transmitters

- Control Valves

- Controllers / Positioners

- Gauges

- Sensors

- Thermocouples and Thermocouple Assemblies

- Level switches

- RTDs-Resistance Temperature Detectors

- Instrument Manifold

- Accessories

- Wire Products

- Wireless Products

- Detectors

- Miscellaneous products

- Alarms and signaling devices

- Gas Detectors

- Gas Monitoring Systems

- Flame Detectors

- Hart communication tool

- Hydrostatic level probes

- Displays / Digital indicators

- Thermowells

- Thermometers

- Power supplies, Isolators, Signal converter

- Automotive Equipment

- Signal generators

- Data-loggers, Recorders

- Humidity and Temperature Transducer

QUICK ENQUIRY

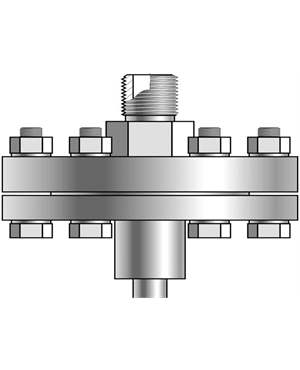

Threaded Diaphragm Seal

Threaded diaphragm seals provide dependable protection for pressure instruments operating in demanding process environments. They isolate sensitive pressure transmitters and gauges from aggressive, viscous, or sanitary media, maintaining measurement accuracy while preventing process contamination or clogging.

Filter By

How Threaded Diaphragm Seals Work

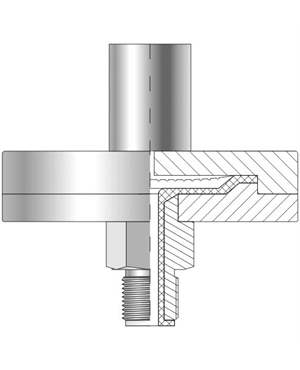

A threaded diaphragm seal acts as a barrier between the process medium and the measuring instrument. The flexible diaphragm transmits pressure hydraulically via a fill fluid to the sensor, while isolating it from direct contact with the process material.

This design protects instruments from:

• Corrosive or clogging media

• High-viscosity fluids or crystallizing compounds

• Sterile or sanitary process conditions requiring full isolation

As a result, threaded diaphragm seals extend instrument service life, improve measurement reliability, and minimize maintenance downtime.

Distinct Advantages of Threaded Diaphragm Seals

Engineered for accuracy and protection, threaded diaphragm seals combine mechanical strength with hygienic construction.

Key Highlights:

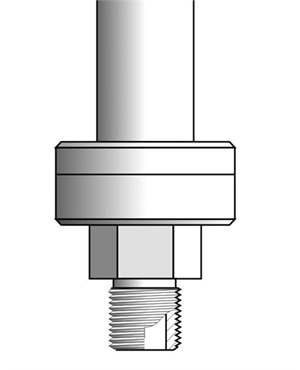

• Secure Threaded Connection: Provides a leak-tight and vibration-resistant seal.

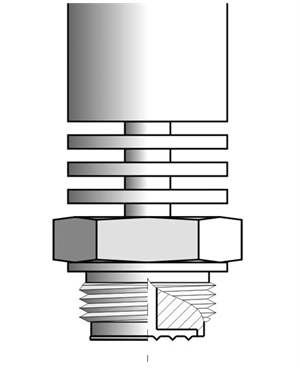

• Pressure Range Capability:Suitable for high-pressure service up to 10 MPa (model-dependent).

• Process Isolation: Prevents contamination and protects sensing elements from aggressive media.

• Material Flexibility: Available in stainless steel, Hastelloy®, or chemically resistant coatings.

• Sanitary Construction: Ideal for food, beverage, and pharmaceutical processes.

• Temperature Stability: Maintains accuracy under fluctuating temperature or pressure.

• Custom Fill Fluids: Optimized for media compatibility and temperature range.

These seals are designed to meet the hygienic and performance standards demanded in precision pressure measurement applications.

Where Threaded Diaphragm Seals Add Value

Threaded diaphragm seals are used wherever precise pressure measurement must be achieved without exposing transmitters to harsh or viscous process media. Their design ensures stable, contamination-free signal transfer and long service life.

They excel in:

• Hygienic Systems:Clean-in-place and sanitary applications.

• Corrosive Media: Chemical and refining processes.

• Viscous Fluids: Oils, lubricants, and slurries.

• Abrasive Liquids: Wastewater and filtration systems.

• Compact Installations: Reliable sealing in confined or high-vibration setups.

This combination of protection and accuracy makes threaded diaphragm seals a trusted solution for critical and high-purity pressure applications.

Technical and Design Highlights

Our threaded diaphragm seals are built for reliable pressure isolation and stable signal transfer in sanitary and process applications. Each model including SCOMP, SCOMP 10MPa, SCOMPCH, and SMAZUT features a large-area diaphragm for high sensitivity and accurate measurement.

Key Specifications:

• Connection: Threaded design for tight, vibration-resistant sealing.

• Pressure Range: Up to 10 MPa, model-dependent.

• Design Options: Standard, chemical-resistant, and high-viscosity versions.

• Material: Stainless-steel construction for durability.

• Filling Fluid: Silicone oil or media-specific alternatives.

These seals ensure long-term accuracy and media isolation across sanitary, chemical, and industrial systems.

Frequently Asked Questions (FAQs)

1. What is a threaded diaphragm seal?

It’s a pressure isolation device that protects the measuring instrument from direct contact with the process medium using a threaded connection.

2. Where are threaded diaphragm seals typically used?

They’re used in hygienic, chemical, and industrial processes that involve viscous, corrosive, or high-purity media.

3. What materials are available for diaphragm seals?

Common materials include stainless steel, Hastelloy®, and specialized corrosion-resistant alloys.

4. How do threaded diaphragm seals differ from flanged types?

Threaded seals offer compact installation and are ideal for smaller process connections or confined spaces.

5. Can they be used with pressure transmitters and gauges?

Yes they’re designed to integrate seamlessly with transmitters, gauges, and switches across various brands.

.webp)