Know Everything About the Benefits, Applications, Types, and Automation of Control Valves

Brian Craig

August 01, 2018

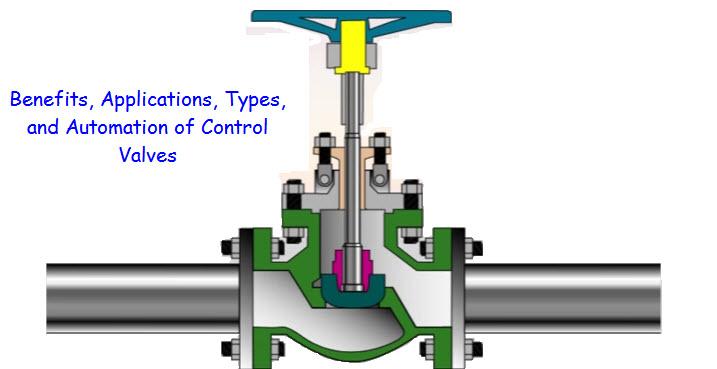

A vast variety of equipment and machines are used in different industries, in order to carry out various processes efficiently, and smoothly. One such widely used equipment employed in most industries for process control applications is a control valve. These valves come in different types, and have different construction, physical properties, features, and applications. However, the main objective of these industrial equipment remain the same – to control the flow of fluid by adjusting the flow passage, with the help of a controller. They are considered to be an extremely important asset for a process control industry. Why? Due to a number of benefits offered by them. Are you intrigued to know what these benefits are? Read the following post, which focuses on the several benefits of the control valves that make them special.

The Benefits that Make Control Valves Popular in Most Industrial Applications

Over the years, the control valves have gained immense popularity across various industries. The following are some striking benefits of these process control valves:

- Direct Benefits

- Easy to Install: The most fundamental, yet important benefit of the process control valves is that they are easy to install. This helps save considerably on the time and efforts.

- Automatically Operated: This is another important benefit. These valves can be operated automatically. This means, it removes the dependency on the operator to open and close the valve.

- Helps Prevent Clogging: The control valves are designed in such a way that the flow of fluids through it is not obstructed. It means, these devices do not clog.

- Indirect Benefits

- Environmentally-friendly Solution: The wastage of natural resources is reduced considerably, by employing control valves. This helps one meet global ecological standards, and makes these valves an environmentally-friendly solution.

- A Money Saving Device: Water conservation can be achieved by using the control valves. This helps save a significant cost on the water, as well as sewer bills for large industries.

The Different Types of Control Valves

Based on the application they are used in, there are different types of control valves as follows:

- Ball Valves

- Plug Valves

- Globe Valves

- Gate Valves

The Applications that Use Control Valves

Here are some most common applications of the control valves in different industries:

- Compressor Anti-surge Systems

- Pump Protection Services

- Pulp and Paper Mills

Today, there have been several advancements in the technologies used in most industries, and this has shown effect on the control valves, as well. Valve automation is becoming more and more common nowadays, since it simplifies the entire operation. There are manufacturers and service providers, with whom you can consult for more information on the automated control valves. One such experienced manufacturer of control valves, who has a great knowledge of this trending concept of valve automation, is the Transmitter Shop. The company is known for providing reliable, and cost-effective solutions for your requirements related to the valves.

Related Posts

- Causes & Solutions of Annoying Noise from Control Valves

- Understanding Industrial Control Valves and their Types

- All Important Questions on Control Valves Answered

- 3 Common Control Valve Maintenance Practices

- Know Everything About the Benefits, Applications, Types, and Automation of Control Valves

- How to Select the Right Control Valve for Your Process?

- Calibration of Control Valve Positioner: The Process Discussed

- Control Valve Actuators: Different Types and Failure Modes Discussed

- Calibration Guide for Fisher 3582 Pneumatic Positioner

- How to Do the Periodical Inspection and Maintenance of the Control Valve?

- Temperature Control Valve – Definition and Working Principle

- Reasons to Choose Remanufactured Instrumentation and Control Valves

- Single Acting vs. Double Acting Positioners: Pros and Cons

- Complete Hydrogen Gas Safety and Measurement Solutions

- Steam Boiler Drum Level Measurement A Comparison of Control System Technologies

- Furnace Flame Sensor Faults Everything You Need to Know for Safe Operation

- Comparison between Multi Valve Manifolds Block Valves and Bleed Valves

- Pneumatic Pressure Controllers: A Safe Choice for Hazardous Areas

- Furnace Flame Sensor Faults Everything You Need to Know for Safe Operation

- Pneumatic Pressure Controllers: A Safe Choice for Hazardous Areas

- How Can Greenhouse Gas Emissions Be Reduced?

- A Practical Guide to Vacuum Measurement and Operation

- Understanding Electrochemical Detection: Principles, Techniques and Environmental Application

QUICK ENQUIRY