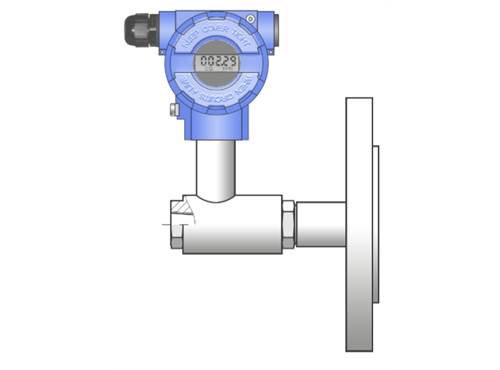

Smart Differential Pressure Transmitter TTS-APR-2000ALW

The APR-2000AL transmitter is applicable to the measurement of differential pressure of gases, vapours and liquids. The active element is a piezoresistant silicon sensor separated from the medium by separating diaphragms and a specially selected type of manometric fluid. The special design of the active sensing element ensures that it is able to withstand pressure surges and overloads of up to 3600/4600/6000/10000 psi. The casing is made of aluminium alloy cast or 316SS stainless steel, degree of protection IP66/IP67. The design of the casing enables the use of a local display, rotation of the display, rotation of the casing by 0–340° relative to the sensor, and a choice of cable direction.

- 4…20 mA output signal + HART 5 / HART 7 protocol (special version: 0…20 mA or 0…5 mA output signal + HART 5 protocol)

- Display with backlight

- Safety version SIL2/SIL3

- Intrinsic safety certificate ATEX, IECEx, FM (USA, Canada)

- Explosion proof certificate ATEX, IECEx, FM (USA, Canada)

- Programmable zero range, shift, characteristic and damping ratio with local panel keys

- Static pressure limit up to 8700psi

- Accuracy 0,075% (0,05%, 0,04% on request)

- Marine certificate – DNV, BV

- Gold plated diaphragms

- Wetted parts material 316L/Hastelloy C276