BLOG

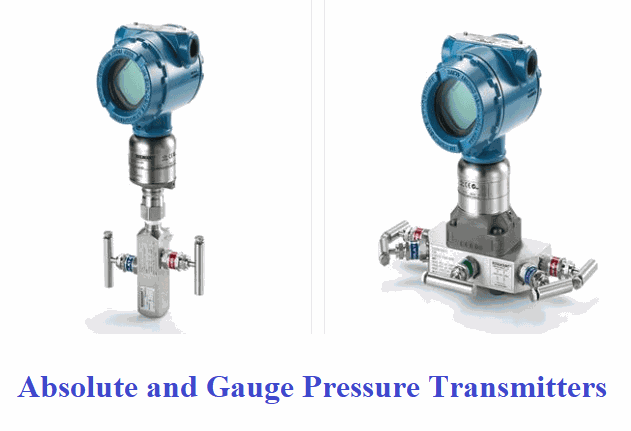

Absolute and Gauge Pressure Transmitters - Overview and Working Principle

Brian Craig

October 06, 2020

Over the years, pressure transmitters are utilized to measure liquid levels of open or pressurized tanks in industrial processes. With rapid digitalization, these transmitters now comprise advanced technology and improved additional features. This advancement guarantees high performance in measurements, process optimization, and operational safety. Initially, pressure transmitters were equipped with capacitance and piezo-resistive technologies. Nowadays, they come with microprocessor-based technologies, thus named smart pressure transmitters. There are different types of pressure transmitters in use today. Absolute pressure transmitter and gauge pressure transmitter are two popular choices. Would you like to know more about them? This post discusses both pressure transmitters in detail. So, stay tuned.

Working Principle and Other Details about Absolute Pressure Transmitters

Often called as absolute pressure sensor, they provide pressure measurement to a reference of zero pressure, which is as close as possible to a vacuum. They use 0°K as a reference point. Thus, there is no comparison in terms of pressure changes.

As discussed earlier, the pressure is measured relative to a complete vacuum with absolute pressure sensors. This mean, the measurements are not influenced by atmospheric pressure such as air or altitude pressure variations. As they are not in contact with the external system, the release node does not exist in the system. The side of absolute pressure transmitters which is not exposed to pressure media is completely sealed. Absolute pressure transmitters are found in applications demanding the monitoring of industrial performance-driven vacuum pumps. For instance, in the food industry, vacuum packing is used to prevent oxygen from degrading perishable foods, thus extending the product’s flavor as well as shelf life.

What Are Gauge Pressure Transmitters and How Do They Work?

For most applications, the vacuum or exact pressure being generated is not important criteria. Instead, you just need to understand what’s the difference between the vacuum and atmospheric pressure. This is where gauge pressure transmitters are used. Often called gauge pressure sensor, they provide pressure measurement relative to the local atmospheric pressure. These sensors have ports to sample the ambient pressure in real-time. A pipe is attached to the port, and a vent is open to the atmosphere. The pipe connects to the system where the actual measurement is to be made.

Gauge pressure can be measured using a variety of techniques. Many of them use a membrane fitted with an electrical component like a resistor, and its value varies when flexed. Today, the microelectromechanical system, often called MEMS, is used. In this, tiny and lightweight structures are fixed into silicon that can vibrate or flex. As the base is silicon, the electronic circuit can be integrated with the MEMS system. The small electrical path ensures low noise as well as high measurement accuracy, while the MEMS system element can result in a sensor that is completely isolated from temperature changes.

If you are someone who is looking for an absolute and gauge pressure transmitter for your industrial application, then make sure you employ a reliable, industry-leading supplier. The Transmitter Shop (TTS) is one industry leader specialized in offering accurately designed and performance-driven pressure sensors from top brands such as Emerson.

Related Posts

Pressure Monitoring in Pump Systems: A Comprehensive Guide

Common Challenges in Air Flow Measurement and How to Overcome Them

Monitoring and Controlling Energy Production in Power Plants

Understanding the Impact of Pressure Fluctuations on Drying Performance

Understanding Pressure Ranges and Units for Fluid System Monitoring

The Benefits and Challenges of HVAC System Balancing

An Ultimate Selection Guide for Flow Transmitters

Procedure to Calculate Accuracy of Pressure Transmitter Discussed

Pressure Transmitters vs. Pressure Transducers: Learn the Differential Characteristics

Multivariable Transmitter: What Is It and How Does It Work?

How Do You Test for 4 to 20mA Signal in a Pressure Transmitter?

Temperature Transmitter: How to Select The Efficient One for Your Application?

Flow Meter vs Flow Transmitter: Know the Difference

HART Communication Protocol: Overview, Working Principle, Benefits in Industrial Automation

What is Absolute Pressure Transmitter & how does it work?

How Do You Calibrate A Flow Transmitter?

Remote Seals: Significance, Working Principle & Applications

How to Select Pressure Transmitter for Your Application?

How to Choose Diaphragm Seals for Your Application?

Difference in Conventional Transmitters and Smart Transmitters

What Are Diaphragm Seals and Their Types?

Rosemount 2088 Vs Rosemount 3051 – A Few Points of Differences Discussed

Rosemount 3051S vs 3051C Transmitter – What is Your Choice?

Impact of Shock and Vibration on Pressure Transducer

Safety Tips for Differential Pressure Transmitter Operation

Factors to Consider When Choosing a Pressure Transmitter Manifold

Tips to Improve the Performance of Pressure Sensors

Important Calibration Tips for Pressure Sensors

5 Most Popular Pressure Transmitter Technologies

Factors of Consideration When Choosing Pressure Transmitters

Tips to Augment the Performance and Service Life of Pressure Transmitter

Factors To Be Considered While Differentiating $40 and $400 Pressure Transmitters

An Unconventional Guide to Selecting the Right Pressure Sensor

3 Major Pressure Transmitter Technologies That Made the Device Popular

The Features and Benefits of Rosemount 1199 Direct Mount Transmitters

What are the Steps Involved in Calibrating Pressure Gauge?

All Important Questions on Reconditioned Transmitters Answered

Is Remanufactured Transmitter a Better Option than a New One?

Differential Pressure Transmitters: How Do They Help in Flow Measurements?

3 Whats that Explain How Often You Should Calibrate Pressure Transducer

Guidelines for Troubleshooting Pressure Transducers

Learn How to Calibrate a Pressure Transmitter – II

Learn How to Calibrate a Pressure Transmitter

Know Three Interesting Uses of Pressure Transmitters