BLOG

All Questions on Smart Transmitters and their Calibration Answered

Brian Craig

May 16, 2018

A huge variety of smart instruments are gaining popularity in the process industry, due to various reasons. These instruments are known to provide several benefits, which are valued in the said industry. Smart transmitters are one such instruments, which are valued for distinct services that they offer. These transmitters have helped process managers optimize value for their investment. Along with all these benefits, the smart instruments have introduced several challenges to the calibration process. Are you intrigued to know what these smart transmitters are? What are best ways to calibrate them? Read the post to find answers to your questions.

What is a Smart Transmitter?

In the process industries, a transmitter is used to measure various process variables, such as temperature, pressure, flow, etc. Typically, a transmitter produces an output signal (an audible alarm) in proportion to the measured value. These signals enable a process owner to take control of their processes in a better way.

Smart transmitters are those new age transmitters, which are equipped with microprocessors. These microprocessors are known for their advanced diagnostic abilities, stability, and accuracy (largely due to the digital compensation of non-linear readings). Additionally, these devices are also connected with a host of other process measuring devices.

Most of these smart transmitters support open standard protocols like HART, FOUNDATION Fieldbus, Wireless HART, or Profibus. However, HART (Highway Addressable Remote Transducer) is the most popular protocol in use today.

What is Calibration? How does it differ from Configuration?

Due to the absence of standardized definitions, calibration is often misinterpreted with other term configuration.

According to industry standards, configuration refers to the adjustment of the transmission, and measurement capabilities of a smart transmitter. In short, it indicates setting the parameters of the transmitter to meet various process requirements.

Calibration is an entirely different procedure. It compares the device against a traceable reference, and comparisons are documented to determine the drift. Although the process requires no major adjustments, still potential adjustments are made, while calibrating the transmitter.

What are the Significant Benefits of Smart Transmitter Calibration?

Although the smart transmitters have digital output, still they are calibrated often to ensure their proper working. Is that all? The following reasons also contribute to the need of regular calibration:

What is the Procedure for Calibrating a Smart Transmitter?

The smart transmitter calibration procedure is known as digital trimming. The digital trimming is performed in these ways:

In both these processes, transmitter is subjected to low-range and high-range value (LRV and URV) stimulus. The stimulus means process variable input to the transmitter. The resulting output is read using a hand-held communicator. The resulting error between the input and output is calculated, and appropriate trimming is performed. The transmitter can be trimmed whenever a serious drift is noticed in the sensor or the converter circuitry beyond a permissible limit.

If you are still new to this concept, it is always better to approach an expert like The Transmitter Shop. The company provides a wide range of transmitter calibration services.

What is a Smart Transmitter?

In the process industries, a transmitter is used to measure various process variables, such as temperature, pressure, flow, etc. Typically, a transmitter produces an output signal (an audible alarm) in proportion to the measured value. These signals enable a process owner to take control of their processes in a better way.

Smart transmitters are those new age transmitters, which are equipped with microprocessors. These microprocessors are known for their advanced diagnostic abilities, stability, and accuracy (largely due to the digital compensation of non-linear readings). Additionally, these devices are also connected with a host of other process measuring devices.

Most of these smart transmitters support open standard protocols like HART, FOUNDATION Fieldbus, Wireless HART, or Profibus. However, HART (Highway Addressable Remote Transducer) is the most popular protocol in use today.

What is Calibration? How does it differ from Configuration?

Due to the absence of standardized definitions, calibration is often misinterpreted with other term configuration.

According to industry standards, configuration refers to the adjustment of the transmission, and measurement capabilities of a smart transmitter. In short, it indicates setting the parameters of the transmitter to meet various process requirements.

Calibration is an entirely different procedure. It compares the device against a traceable reference, and comparisons are documented to determine the drift. Although the process requires no major adjustments, still potential adjustments are made, while calibrating the transmitter.

What are the Significant Benefits of Smart Transmitter Calibration?

Although the smart transmitters have digital output, still they are calibrated often to ensure their proper working. Is that all? The following reasons also contribute to the need of regular calibration:

- Most smart transmitters are exposed to harsh conditions. Thus, these instruments drift over the time.

- As with other industries, the process industry have to fulfill regulatory requirements, such as safety, quality systems, environmental systems and standards, etc.

- Accurate measurements always lead to appropriate decision making, which may bring various economic benefits.

- Regular calibration helps process owners to ensure workplace and employee safety.

- Calibration helps achieve consistent product quality by optimizing processes.

What is the Procedure for Calibrating a Smart Transmitter?

The smart transmitter calibration procedure is known as digital trimming. The digital trimming is performed in these ways:

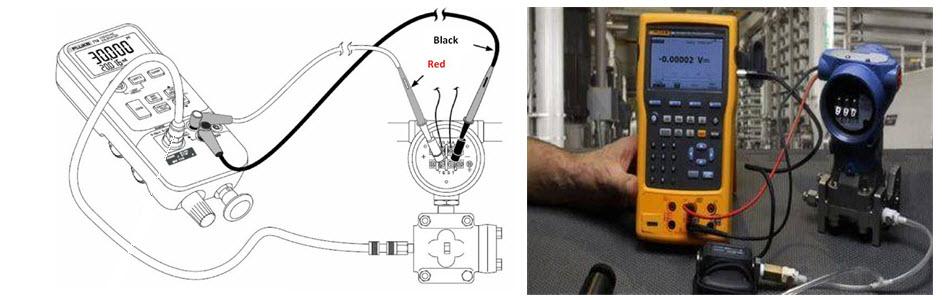

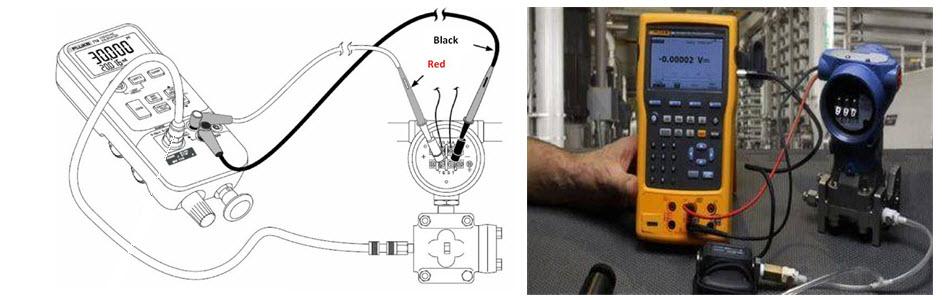

- Current Loop Trim: In this, the output of Digital-to-Analog converter is trimmed.

- A Sensor Trim: In this process, the variable reading of the transmitter is matched to a precision input.

In both these processes, transmitter is subjected to low-range and high-range value (LRV and URV) stimulus. The stimulus means process variable input to the transmitter. The resulting output is read using a hand-held communicator. The resulting error between the input and output is calculated, and appropriate trimming is performed. The transmitter can be trimmed whenever a serious drift is noticed in the sensor or the converter circuitry beyond a permissible limit.

If you are still new to this concept, it is always better to approach an expert like The Transmitter Shop. The company provides a wide range of transmitter calibration services.

Related Posts