Pneumatic Transmitters

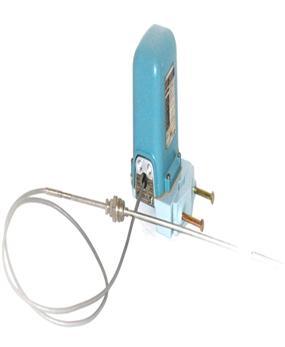

Pneumatic differential pressure transmitters are used in process industries for measuring various variables such as level or differential pressure of fluids such as gas, air, and liquids, or pressure. The value of the measured variable is transmitted as a 3 to 15 PSI pneumatic signal to equipment that is remotely mounted. This remotely mounted equipment may include various types of indicators, recorders, controllers, or the combination of these devices. Looking for a transmitter that brings you accurate results when put to flow, liquid level, density, and low pressure measurement applications? We, at The Transmitter Shop, have a range of Foxboro Pneumatic Transmitters to meet your needs as expected. Our field-proven pneumatic differential pressure transmitters are designed to offer excellent repeatability and long-term stability. They are precise and easy to maintain transmitters that are manufactured to withstand the most demanding applications. Available with a selection of input/output signals with small, compact, lightweight configuration, Foxboro Pneumatic Transmitters fit a wide range of applications across industries.

Types of Pneumatic Transmitters we Offer at TTS

Our name is established as a one-stop-shop provider of all models of Foxboro Pneumatic Transmitters. The following are the models we offer under this category:

-

13HA:

Suitable for use in all process industries, our range of 13 HA Foxboro Pneumatic Transmitters are manufactured to uphold their performance even in the most adverse conditions. It not only measures differential pressure precisely, but can also send the output to respective receives placed in hundreds of meters away. Effortless to install, these transformers assure maximum efficiency and safety. -

43AP:

Designed to measure the difference between process measurement and its set point, Foxboro’s 43AP pneumatic transmitters have become the standard in the industry. These reliable, multipurpose devices are suitable for use in pneumatic control systems and other industrial applications. With thousands of successful, trouble-free installations, you can rest assured of its dependable operation in demanding environments. -

15 A:

With Accuracy ±0.5% of span and repeatability 0.1% of span, these transmitters work best for flow, liquid level, and other differential pressure applications. Operated with the capsule in the vertical plane, 15 A transmitters bring in hysteresis, repeatability, dead band, and drift over one-hour period. -

13 A:

Widely used in flow, liquid level, and other differential pressure measurement applications, Foxboro13 transmitters have been field proven with several installations worldwide. The transmitter is constructed using materials such as 316 stainless steel, Monel (13A4 only), Nickel alloy (a) (13A5 only), which makes these units largely preferred for the most demanding applications. They are calibrated at the factory before shipment -

12 A:

These are yet another flagship products we offer at The Transmitter Shop that contribute to rightly indicate, record, or control the temperature of processes between -220 and +760°C (-350 and +1400°F). These transmitters are designed to ensure stable, dependable operation, owing to their rugged construction using die-cast low copper aluminum alloy, glass-filled polycarbonate cover, waterproof/duct proof housing among others. -

11 AM:

This transmitter range, which works based on force-balanced/p cell mechanism, is designed specifically for accurate differential pressure measurement. Provided with a variety of optional features, these models offer a wide rangeability in a single instrument. With easy and economical servicing, they can be put to use for a long period of time even under strenuous industrial or process conditions. -

11 GM:

Compliance to NACE Standard MR-01-75, these types of Foxboro Pneumatic Transmitters have been installed successfully in several applications over the years. With fully-adjustable spans up to a 10:1 ratio, these transmitters can be chosen when durable and dependable pressure instrumentation is required.

Explore the categories listed and get the technical details and features in detail to make a wise purchase.

Working Principle of Pneumatic Differential Pressure Transmitter

All pneumatic pressure measuring instruments use pneumatic relays and flapper/nozzle sensors. When using these systems, they use the force-balance or motion-balance mechanisms. Of these, the force-balance mechanism is usually preferred. The instrument used for this measurement features a bellow that receives an input signal. This input signal is opposed through a reference signal, which is produced by another bellow. The force produced during the activity is utilized by the lever. Typically, differential force is produced during this process. This lever is positioned on a pivot, which supports it. The pivot can be adjusted according to requirements. This differential force faces opposition by a bellows/spring combination. The nozzle sensor/flapper is usually placed adjacent to bellows.

If the input signal is more than the reference signal, then the resultant force makes the force bar to rotate in a clockwise direction about the pivot. In this situation, the flapper goes near the nozzle, and the pressure in the output bellows continues to increase until the force bar equilibrium is established. The output pressure will change according to the measurement signal. This generates a 3-15 PSIG signal, which is a standard signal.

Industries that Use Pneumatic Transmitters

With maximum efficiency and assurance of operating economies and safety, Foxboro Pneumatic Transmitters find immense applications across industries. Manufactured in compliance with several industry standards utilizing the best of materials, the models we offer bring you the accurate results when used in the following sectors.

- Energy

- Beverage

- Pharmaceuticals

- Water

- Defense

- Oil and gas treatment

- Water Treatment

- Chemical / Petrochemical / Refining

- Nuclear Power

- Power Generation

- Pulp and Paper Mills

- Medical

- Laboratories

With convenient and customizable solutions, we at The Transmitter Shop, bring you the right products that best suit the application. We have a strong customer service focus, which enables us working closely with you.