Our Top Brands

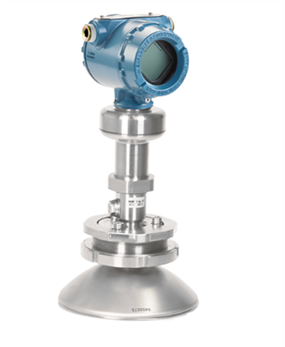

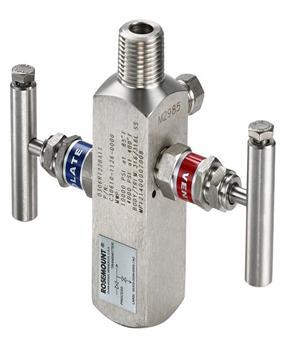

Rosemount

Best Seller

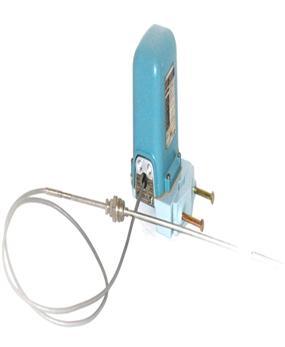

Foxboro

Best Seller

Fisher

Best Seller

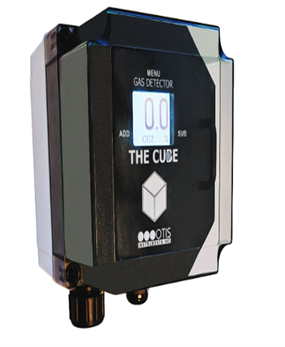

Otis Instruments

Best Seller

E2S Warning Signals

Best Seller

PR Electronics

Best Seller

TTS

Best Seller

Bourdon

Best Seller